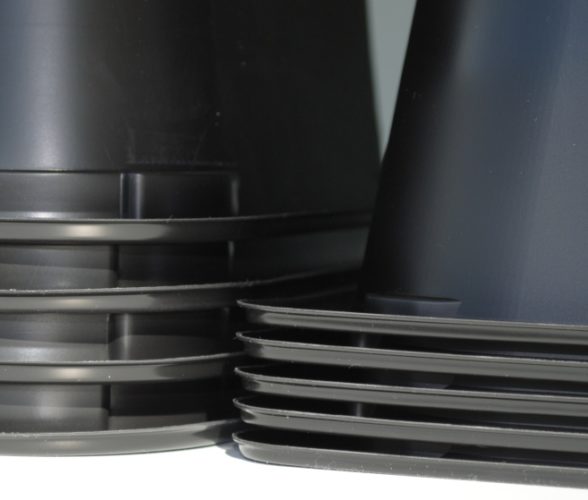

Trays may appear to be very similar, yet every product can be prepared in many different ways. Each decision influences their storage conditions, weight (price), warehousing possibilities, colour and transparency.

We always offer our clients full service meaning we always start by determining the needs. We can then offer our solutions so that in later phases you will have the least amount of problems.

As we produce our own PP and rPET plastic we can take into consideration the final product’s needs and peculiarities already when producing the raw material.